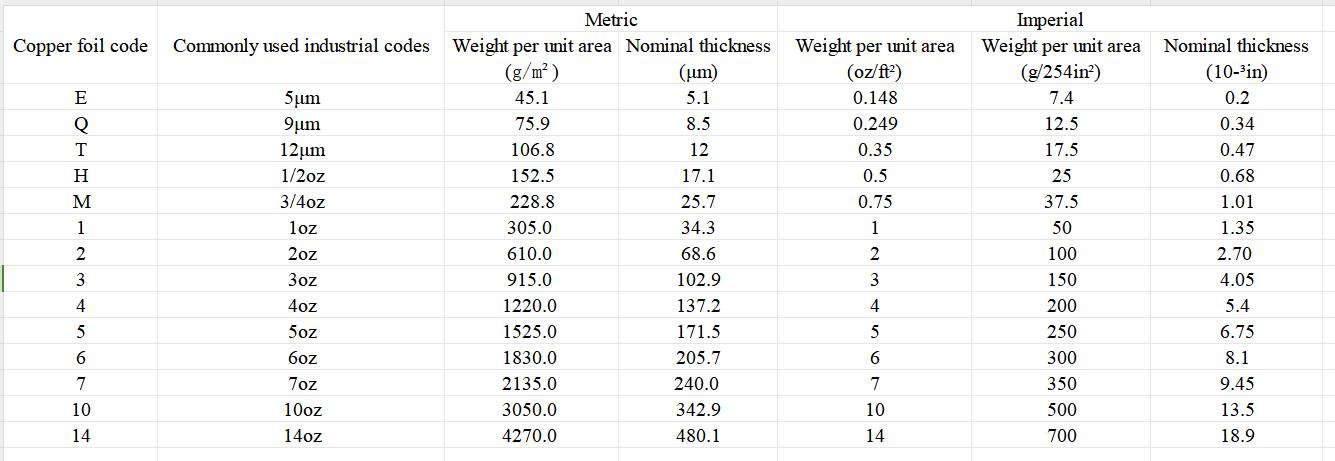

Dhumucda iyo miisaanka xaashida naxaasta ah(laga soo xigtay IPC-4562A)

Dhumucda naxaasta ah ee PCB-ga looxa-maxaasta ah waxa sida caadiga ah lagu muujiyaa ounces imbarayaal (oz), 1oz=28.3g, sida 1/2oz, 3/4oz, 1oz, 2oz. Tusaale ahaan, baaxadda bedka 1oz/ft² waxay u dhigantaa 305 g/㎡ unugyo metrik ah. , oo lagu beddelay cufnaanta naxaasta (8.93 g/cm²), oo u dhiganta dhumucdiisu tahay 34.3um.

Qeexida xaashida naxaasta ah "1/1": bireed naxaas ah oo leh bedka 1 cag laba jibaaran iyo culeys 1 wiqiyadood; ku faafi 1 wiqiyadood oo naxaas ah si siman saxan leh aag 1 cagood oo laba jibbaaran.

Dhumucda iyo miisaanka xaashida naxaasta ah

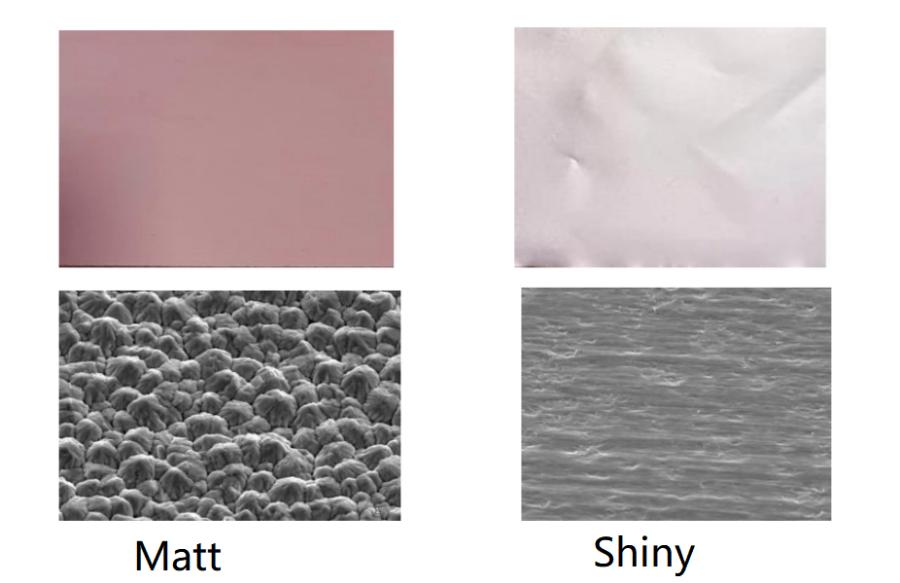

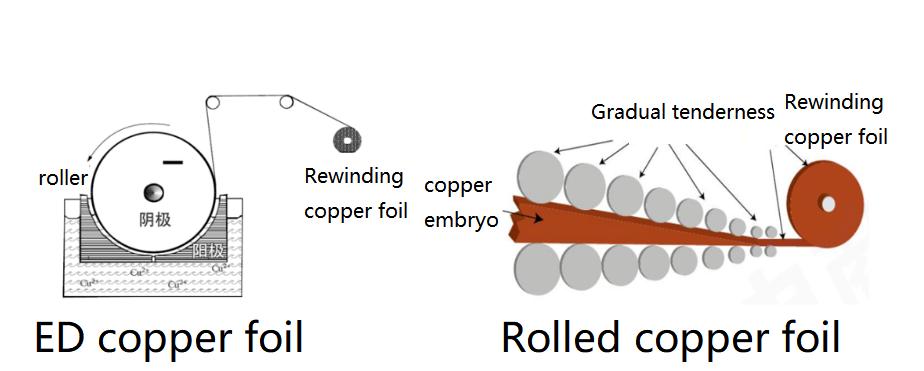

☞ED, foil naxaas ah oo Electrodeposited (ED copper foil), waxaa loola jeedaa bireed naxaas ah oo lagu sameeyay korantada. Habka wax-soo-saarku waa habka korantada. Qalabka Electrolysis guud ahaan wuxuu isticmaalaa rullaluistemadka dusha ka samaysan walxaha titanium sida rullaluistemadka cathode ah, daahan oo tayo sare leh milmay sunta rasaasta ku salaysan ama daahan titanium ku salaysan daxalka u adkaysta oo aan milmayn sida anode ah, iyo sulfuric acid waxaa lagu daraa inta u dhaxaysa cathode iyo anode. Electrolytka Copper, ee hoos yimaada ficilka hadda tooska ah, wuxuu leeyahay ions bir ah oo naxaas ah oo lagu dhejiyay rullaluistemadka cathode si ay u sameeyaan foorno asal ah oo elektrolytic ah. Sida rullaluistemadka cathode uu sii socdo inuu wareego, bireedkii asalka ahaa ee la soo saaray ayaa si joogto ah loo dhejiyaa oo laga fujiyaa rullaluistuyada. Kadibna waa la dhaqaa, la qalajiyey, oo lagu dhaawacay duub duub oo ceeriin ah. Naxaas nadiif ah oo bireedku waa 99.8%.

☞RA. Naxaasta naxaasta ah ayaa loo istcimaalay sida maaddada aasaasiga ah, kaas oo la guray, la miiray, iyo kuleyl la duubay oo la duubay (jihada dheer) heerkulka ka sarreeya 800 ° C marar badan. daahirnimo 99.9%.

☞HTE, heerkulka sare ee elongation electrodeposited bireed naxaas ah, waa bireed naxaas ah oo ilaaliya dherer aad u fiican heerkulka sare (180°C). iyaga ka mid ah, elongation of bireed copper leh dhumucdiisuna waxay of 35μm iyo 70μm heerkulka sare (180 ℃) waa in lagu hayaa in ka badan 30% ee elongation heerkulka qolka. Sidoo kale loo yaqaan HD foil naxaas ah (foil naxaas ah oo aad u sarreeya).

☞DST, daawaynta labajibbaaran ee bireed naxaasta ah, waxay rogtaa labada sagxadood ee siman iyo kuwa qallafsan. Ujeedada ugu weyn ee hadda waa in la dhimo kharashyada. Roughing dusha siman waxay badbaadin kartaa daaweynta dusha naxaasta iyo tillaabooyinka browning ka hor lamination. Waxaa loo isticmaali karaa sida lakabka gudaha ee foornada naxaasta ah ee looxyada lakabyada badan, uma baahna in la bunni (madow) ka hor inta aan laminating looxyada lakabyada badan. Khasaaraha ayaa ah in dusha naxaasta aan la xoqin, wayna adagtahay in la saaro haddii ay jirto wasakh. Waqtigan xaadirka ah, codsiga xaashida naxaasta ee la daweeyay ee laba-geesoodka ah ayaa si tartiib tartiib ah u yaraanaya.

☞UTF. Kuwa ugu caansan waa foils naxaas ah oo ka hooseeya 9μm, kuwaas oo loo isticmaalo looxyada wareegyada daabacan ee soo saarista wareegyada wanaagsan. Sababtoo ah xaashida naxaasta ah ee aadka u dhuuban way adag tahay in la xakameeyo, guud ahaan waxaa taageera side. Noocyada sidayaal waxaa ka mid ah bireed naxaas ah, bireed aluminium, filim organic, iwm.

| Koodhka foil naxaasta | Xeerarka warshadaha ee sida caadiga ah loo isticmaalo | Metric | Imperial | |||

| Miisaanka halkii unug (g/m²) | Dhumucda magacaaban (μm) | Miisaanka halkii unug (oz/ft²) | Miisaanka halkii unug (g/254in²) | Dhumucda magacaaban (10-³in) | ||

| E | 5μm | 45.1 | 5.1 | 0.148 | 7.4 | 0.2 |

| Q | 9μm | 75.9 | 8.5 | 0.249 | 12.5 | 0.34 |

| T | 12μm | 106.8 | 12 | 0.35 | 17.5 | 0.47 |

| H | 1/2oz | 152.5 | 17.1 | 0.5 | 25 | 0.68 |

| M | 3/4 oz | 228.8 | 25.7 | 0.75 | 37.5 | 1.01 |

| 1 | 1oz | 305.0 | 34.3 | 1 | 50 | 1.35 |

| 2 | 2oz | 610.0 | 68.6 | 2 | 100 | 2.70 |

| 3 | 3oz | 915.0 | 102.9 | 3 | 150 | 4.05 |

| 4 | 4oz | 1220.0 | 137.2 | 4 | 200 | 5.4 |

| 5 | 5oz | 1525.0 | 171.5 | 5 | 250 | 6.75 |

| 6 | 6oz | 1830.0 | 205.7 | 6 | 300 | 8.1 |

| 7 | 7oz | 2135.0 | 240.0 | 7 | 350 | 9.45 |

| 10 | 10oz | 3050.0 | 342.9 | 10 | 500 | 13.5 |

| 14 | 14oz | 4270.0 | 480.1 | 14 | 700 | 18.9 |